| WeChat: +86.13328318872 | Home | InSite Search | About Us | Contact Us |

|

|

|

||

|

||||

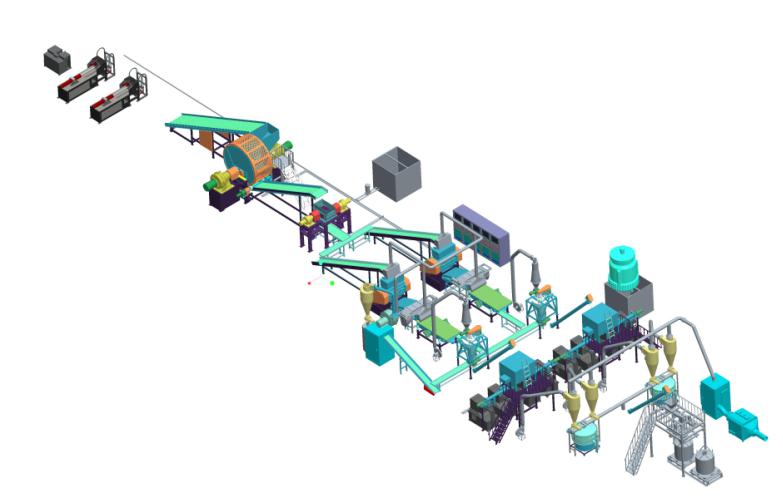

Rimpex@RPM supplies waste tyres recycle line, including waste tire bead cutter, waste tire bead extractor, waste tire crusher, secondary shredder, fine rubber shredder, airflow classifier, vibrator, rubber grinder, dust remover, cartridge style ash catcher, auto bag filler, and also with computer control system for waste tyres recycle line, the manufacturer offers int'l after services of installation & commissioning.

|

We mainly focuses on the research, exploration, production and marketing of waste tire recycling equipment, as well as application technology of crumb rubbers. At the same time we can provide all kinds of services for customers such as mechanical design, manufacture, installation, adjustment, and staff training. We will meet your specific requirements and provide customized products. We now has more than 100 employees, possesses a manufacturing base with annual processing capacity of 150,000 tons of waste tires, and has a worldwide marketing network.

Particularly in dealing with waste tire recycling technology, we are at an advanced level at home and international fields. The major economic and technical indicators of the complete production line extracting rubber powder from waste tires are now in the leading position in this field both at home and abroad. The considerable application of the technology shall eradicate the black pollution formed by present piles of waste tires, which represents great economic efficiency and social benefits.

Nine years' efforts have made us open Russian, Iran, Hong Kong, Malaysia, China Mainland and other countries, with high reputation among customers.

"Concentration, Professional, Technology Innovation, Constantly passing Sustainable progress" is our business philosophy. We warmly invite clients both from home and abroad to visit ourcompany for inquiring, keeping technical and business contacts. We are going for developing a worldwide range of economic and technical cooperation, even find the agent of our tire recycle machine.

The Production Process for Waste Tire Recycling Machinery

1. Waste Tires --> 2.Tire Cutter --> 3. Wire Bead Extractor --> 4. Tire Crusher --> 5. Secondary Crusher --> 6. Secondary Rubber Shredder --> 7. Magnetic Separator --> 8. Square Magnetic Separator --> 9. Third Rubber Shredder --> 10. Magnetic Separator --> 11. Square Magnetic Separator --> 12. Airflow Classifier- --> 13. Storage Bin --> 14. Rubber Grinder --> 15. Airflow Classifier --> 16. Three-layerviratory Screen --> 17. Auto Bag Filler

Four Features of Waste Tyres Recycle Line

- To granulate radial tires into fine rubber crumb of 40~120 mesh with steel and fiber completely recycled at ambient temperature.

- Tight construction, small space and simple technique flow.

- Low energy-consuming and good performance-cost ratio

- Hight automatization, fewer labours requirement

Features of Machinery Set of Waste Tires Recycle Line

- Tight construction, fine layout, small space, 600sqm only for FCC 10,000, lower investment and operating cost.

- Low energy consuming, 811kW/hour only for 10,000 which is the lowest power cost in this industry.

- Two types of handle control and automatic control by different customer

- The whole input tires, after the processing, steel are completely separated and fiber can be separated up to 99% or above. The finish product is high and competitive in the market

- The finished line output size can be made into 5-15 mesh ,15-30 mesh grains, 40-100 mesh powder and other specifications

- Unique design, high output and long lifetime blade characterize secondary shredder and fine rubber shredder, which can improve the working efficiency and lower equipment maintenance cost.

- In line have dust remover ,equipment running pollution-free, no fine dust, no fiber fly in the shop, meeting the environmental requirement of the government.

- Have operation instruction , simple operation.

- 5-7 People required for FCC3000 with automatic control system, 6-8 People required for FCC5000 with automatic control system, 8-10 People required for FCC10000 with automatic control system (May be based on truth add/reduce people)

- Reasonable construction, easy operation and low rate of breakdown.

Wire Bead Cutter GQC350 The GQC350 bead cutter is one equipment that beading the tire with the outer diameter ≤1200mm tire under normal temperature, its goal is to judge the tire, for facilitating the following wiredrawing working procedure march. Its structure mainly includes: The motor, the tire baffle, the guidance board, the blade, the pulley, the rack, the oil cylinder, the hydraulic pressure stand and so on the spare parts. Working princeple: Advantages:

|

Waste Tire Bead Extractor LJS1250 Bead extractor is a device to mechanic method to pull out the bead of a tire under ambient temperature; the purpose is to protect the subsequence blades in other machines in the whole processing system. The main parts include: motor, tire baffle, hook, pulley, frame, pulling device, pressing device, hydraulic pressure, etc. Working principle: Advantages:

|

Waste Tire Crusher PSJ1200 Tire crusher is applicable for both radial tire and bias tire. This device is designed to crush tires into blocks of 50*50 cm for further processing. It is formed with in feed funnel, motor, gear transmission system, crushing chamber, classifier, main body, etc. Working principle: Advantages:

Easy shaft replacement and maintenance.

|

Waste Tire Crusher PSJ500 This machine is mainly used to crush the 50*50mm thick tire crumb(from the big tire crusher PSJ1200) to 25*25mm thin tire crumb. Working principle: Advantages:

|

Secondary Shredder XJZ series Working principles: Advantages:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fine Rubber Shredder XJX Series Fine rubber shredder XJX series:This machine is to smash 6-12mm rubber processed by tire crusher into 1-4mm rubber crumb in ambient temperature. It's composed of main axis, movable sword-plate, movable sword, running wheel, stable sword-seat, stable sword, filter, in-filler and in-out circular water cannula, etc. Working principles: Advantages:

|

Airflow Classifier QWF40 Working principle: Advantages:

|

|||||||||||||||||||||||||||||||||||||

Square Magnetic Separator Working principle Advantages:

|

XJFS-280 Rubber Grinder Advantages: Main parts and usage:

|

Dust remover Working principle Advantages: |

Cartridge Style Ash Catcher (CSAC) Working principle: |

SZ2001P Auto Bagfiller Auto bagfiller adopts advance-program control, which is suitable for the quantities filling of the powder materials with good fluidity. The structure consists of: feeding funnel, feeding device, bag inserting device, weighing device, weighing control cabinet, weighing sensor, weighing control cabinet, Programmable controller, frequency governor, control panel, main body ,etc. Working principle: Features:

|

Features of computer control system

|

Application of Waste Tire Derived Rubber Crumb

Application fields

- Sports ground

track field, school play ground, swimming pool arounding, garden alleys, bowling ground, kindergarten ground, gaming ground, tennis and basketball ground, etc.- Auto industry

road belt for busy area, safety belt, steeling wheel cover, brake sleeve, sealing strip, buffer, mud defender, tire interleaver- Building and equipment

binding and sealing material, hospital, company, bathroom floor, insulation material, under-mat, livestock mat, pressing material, braker, casting material , printing, dam, warehouse, pool, waste material disposing station, house covering and sealing, signboard, water material, rubber sheet, shaking proof material, ring mat, rooftop and wall waterproofing material.- Construction and asphalt

drain pipe, rubberized asphalt, filter, earth modulation and surface covering, washing water pipe, railway crossing, auto & walkway signing obstale, stuff at railway joint and road cracks, daily maintenance material at shipping industry.Application for different size of rubber crumb

- 8-20 raw material for floor, wall,field & track ground, mats, etc

- 30-40 reclaimed rubber, activated crumb rubber, road construction, rubber board, etc

- 40-60 rubberized plastic, water proof material, sole material, etc

- 60-80 tire,rubber product,building material, etc

- 80-120 rubber product, military product, etc.

Go Back Rubber Machinery Center

| Copyright © Rimpex@RPM Since 2002 www.rubberimpex.com Sitemap XIAMEN RPM IMP.&EXP. CO.,LTD. |