|

|

|

|

|

|

||||

| Made in China |

|

Medical Dental Grade TPI Granules, Synthetic Gutta Percha, Trans PolyIsoprene, TPI, Trans Isoprene Rubber, Trans-1,4-PolyIsoprene |  |

V-Belts |  |

China Largest Manufacturer of Meteorological Balloons | ||

| Frozen Trimming Machine, Model NS-60T EUR42,490/SET FOB SHANGHAI, CHINA, including: OBD cyclone separator, 1 set Metal hose 1.5 m, 1 pcs Low temperature special thickened insulated exhaust pipes, 160x1m, 2pcs Aluminum corrugated exhaust pipes, 150 and 200 each 1 set Spare parts and consumables, 1 set The price is on EUR100=RMB754 basis, if the exchange rate fluctuates more than 1%, the prices should be adjusted in last payment according to "Bank's Buying Rate" in http://www.boc.cn/sourcedb/whpj/enindex.html Payment by 30% T/T prepayment, 70% T/T payment before delivery. Lead Time: 20 days after Seller's receipt of prepayment |

|

|

|

| No. | Description | Model | Qty | Unit | EUR |

| 1 | Automatic Jet Freezing Trimming Machine | NS-60T | 1 | Set | 42,490 |

| 2 | Equipments Shipped with the Machine (including the Following Parts) | 1 | Set | Included | |

| 2.1 | OBD Cyclone separator | 1 | Set | ||

| 2.2 | Metal Hose | Length 1.5m | 1 | pcs | |

| 2.3 | Low Temperature Resistant Special Thickened Insulation Exhaust Pipe | Φ160 Length 1m | 2 | pcs | |

| 2.4 | Aluminum Corrugated Exhaust Pipe | Φ150 & Φ200 each 1pcs | 1 | Set | |

| 3 | Consumables | 1 | Set | Included | |

| 4 | Shipping Cost To Shanghai, China | 1 | Set | Included | |

| 5 | After-sales Service | 1 | Set | Included | |

| 5.1 | Installation Design Plan (Installation Master Plan) | ||||

| 5.2 | Helps to Buyer's Technicians/Engineers on Installation and Commissioning | ||||

| 5.3 | Staff Training, 2 Days | ||||

| 5.4 | Quality Guarantee | ||||

| Additional Remarks: 1. Product introduction, technical performance indicators and main component configurations are attached independently.. 2. A list of the wearing parts is attached independently. 3. The installation plan is attached separately. 4. The quality assurance period is 1 year, the use time is not more than 2000 hours, whichever comes first; after receiving the customer's failure notice within the quality assurance period, the response is within 1 working day, but the violation except for malfunctions caused by man-made reasons such as operation and disassembly. 5. The above prices do not include: 5.1. The equipment is moved in and installed in place; 5.2. Public works piping construction; 5.3. Pipeline construction for liquid nitrogen input and nitrogen discharge; 5.4. Other foundations, floors, partitions, explosion-proof, lighting, ventilation and other related equipment. |

|||||

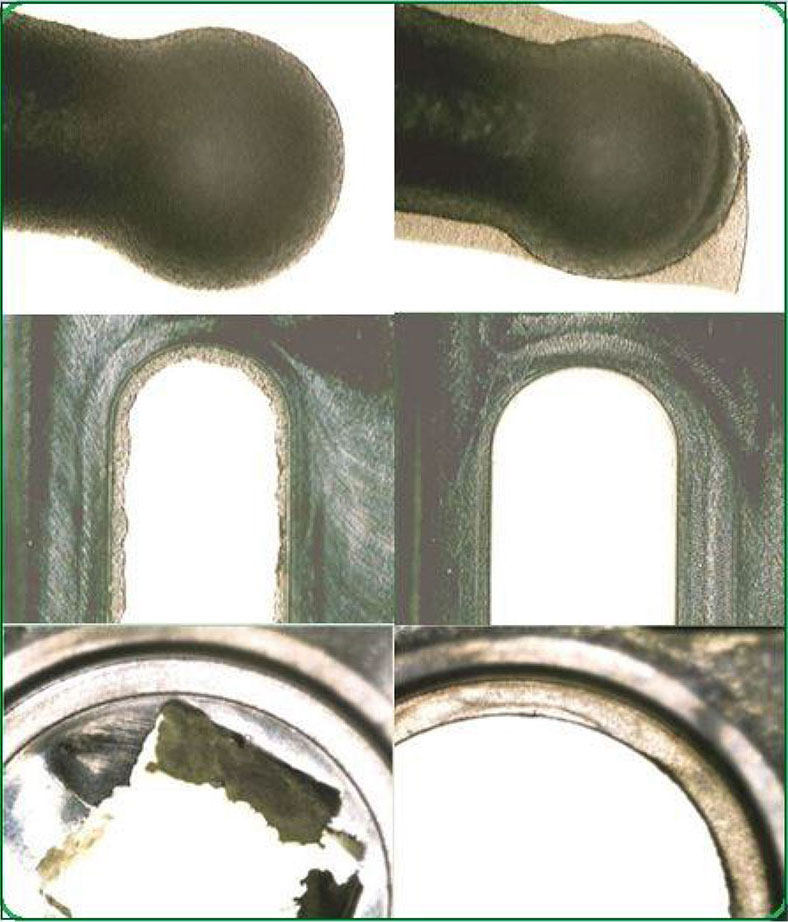

Appendix 1: Product Introduction The frozen trimming process is suitable for rubber, injection molding, zinc-aluminum-magnesium alloy and other materials. It has the characteristics of not damaging the product, high processing precision and wide application. Compared with other trimming methods, the frozen trimming has high precision and high efficiency. Low cost, environmental protection and no pollution! With the accumulation of 40 years of frozen trimming technology in Japan, the automatic jet trimming machine is researched & developped & manufactured by the core technology team jointly established by China and Japan. With the most advanced product models in Asia, it has the widest coverage and the highest market share in Asia. |

||||||||||||||||||||||||||||||||||||||||||||||||||

The frozen trimming machine has corresponding special models for different product materials. |

||||||||||||||||||||||||||||||||||||||||||||||||||

Appendix 2: Technical performance index of NS-120T automatic jet type frozen trimming machine

|

||||||||||||||||||||||||||||||||||||||||||||||||||

Appendix 3: Main components configuration of NS-120T automatic jet type frozen trimming machine

|

||||||||||||||||||||||||||||||||||||||||||||||||||

Appendix 4: List of consumables (The below pictures are for reference only. Please refer to the actual product for details.)

|

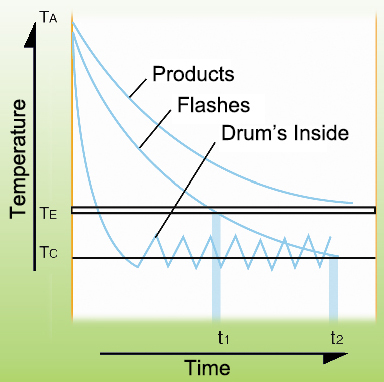

Principle of Frozen Trimming Machine |

|

The automatic jet type frozen trimming machine is a kind of ultra-low temperature using liquid nitrogen to rapidly embrittle the flashes of rubber, plastic products and magnesium alloy products, and in this state, the high-speed jetted frozen particles hit the product's edges. It is a special trimming device that can remove the flashes of the products with high quality and high efficiency while maintaining the physical properties of the rubber, plastic products. |

|

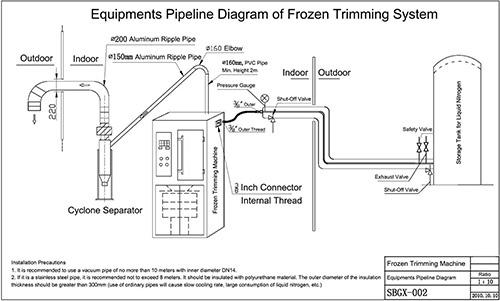

Overall Planning of Frozen Trimming System |

|

|

| Equipment Advantages of Frozen Trimming Machines: High Efficiency, Low Cost, High Quality | |||

| Handling product: O-ring Material: NBR Size: Fi 20 Number of treatments: 400,000 |

Quality | Efficiency | Cost |

| Artificial trimming | <80% trimming pass rate | 5,000pcs/shift/worker Completed by 80 trimming workers in 1 shift |

Workers: 80 workers Inspection: 10 workers Repair: 10 workers Venue: 80m2 |

| Frozen trimming | >99% trimming pass rate | 410,000pcs/shift Completed by 1 set of frozen trimming machine in 1 shift |

Time savings of 95% Mold costs reduced by 40% Rubber costs reduced by 30% Site occupancy reduced by 85% 98% reduction in manual quantity |

Technical Features of Frozen Trimming Machine: As early as the 1970s, the frozen trimming process has been applied in Japanese manufacturing, and we have had decades of research and development experiences on it. In China, our market share is always the highest. We serve the widest range of industries. We are the largest retailer of the frozen trimming machines with the most complete service system. 1. The frozen trimming machine has a corresponding special model for particular product material. At present, there are different types of frozen trimming machines such as NS-60C, NS-60T, NS-120C and NS-120T. |

Functions of Frozen Trimming Machine: 1. It can remove the edges/flashes of the complicated shaped parts. |

|

| Models and Main Technical Parameters of Frozen Trimming Machine | ||

| Item | NS-60C/T (small device) | NS-120C/T (large equipment) |

| Sizes | 1,160L*1, 100W*1,955H (mm) | 1,400L*1, 350W*2, 300H (mm) |

| Weight | 800 kgs | 1,800kgs |

| Power | AC380V, 3ph, 5.5kW | AC380V, 3ph, 8kW |

| Maximum Speed | Max. 7,200rpm | Max. 6,000rpm |

| Set Tempreture | -130~50 Celsius Degree | -130~50 Celsius Degree |

| Volume | 50PCs [general] | 90PCs [general] |

| Throwing Wheel | Fi 250mm | Fi 350mm |

| Control Method | Button/Touch Screen | Button/Touch Screen |

Frozen Trimming Machine Ordinary Button Type NS-60C, 60Liter NS-120C, 120Liter |

Frozen Trimming Machine, Touch Screen Smart Type NS-60T, 60Liter NS-120T, 120Liter |

Frozen Trimming Machine, Touch Screen Plus Scanner, Smart Type NS-60T, 60Liter NS-120T, 120Liter |

Frozen Trimming Machine Precise & Capacity |

If the thicknesses of the edges are suitable, the trimming precise could reach 0.001mm. Generally, the trimming efficiency as below: 60L frozen trimming machine, 3kgs/cycle, 25kgs/hr 120L frozen trimming machine, 5kgs/cycle, 40kgs/hr |

| Processing Cost of Frozen Trimming Machine |

||

| Usually, the processing cost of Frozen Trimming Machine is: 60L equipment Liquid nitrogen: 50kgs/hr, 1RMB/kg, 50RMB Projectile: 0.2kgs/hr, 130RMB/kg, 26RMB Hydropower: 5kW/hr, 5RMB Total cost: 81 RMB/hr 120L equipment Liquid nitrogen: 70kgs/hr, 1RMB/kg, 70RMB Projectile: 0.3kgs/hr, 130RMB/kg, 39RMB Hydropower: 8kW/hr, 8RMB Total cost: 117RMB/hr |

Usually, the processing efficiency of the device is: 60L equipment 3kgs/cycle, 25kgs/hr, 200kgs/day 120L device 5kgs/cycle, 40kgs/hr, 320kgs/day |

And so, the processing cost is about: 60L equipment: 3.24RMB/kg 120L equipment: 2.92RMB/kg |

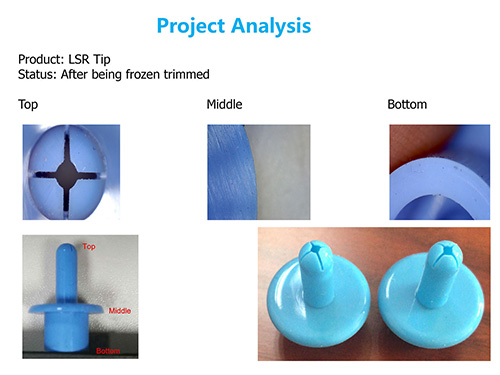

Project Analysis of Frozen Trimming Machinery Product: LSR Tip Status: After being frozen trimmed |

|

|

Production Capacity of 60L Frozen Trimming Machine Calculated in 8 working hours per day:

Daily capacity = single batch throughput (kgs) * number of processing per hour * working hours

=4*6*8 =192kgs Conservative estimation, based on working hours, the 8-hours daily processing capacity is 192kgs |

Technology and Advantages of Frozen Trimming Machinery Advantages of the frozen trimming machines: 1. High processing efficiency: To process products in batches in a short time, and its efficiency is much higher than manual operations'. High-efficiency and high-yield can greatly save the cost of employing people and create more profits. 2. The processing quality is reliable: The products are processed by the machine, in the whole process of operations, the participation of worker is very low, the processing quality of the products is not affected by the state of the worker, and the quality can be maintained consistently. 3. Reducing scrapping: The workers processing soft rubber products, in the event of mistakes, may damage the appearance of the products, resulting in products scrapping, and the process of freezing and trimming can maintain accurate processing and eliminate unnecessary cost waste. 4. The applicability of the machine is wide: The machine can not only deal with the burrs of soft rubber products. For other zinc alloys, rubber, silica gel and specific plastic products, as long as the burrs can be controlled within a reasonable thickness range, the process can be used. 5. The equipment uses liquid nitrogen as the refrigerant (the liquid nitrogen returns to the atmosphere after gasification), and has a dedicated dust collector, which is absolutely environmentally safe. |

Go Back Rubber Machinery Center

| Copyright © Rimpex@RPM Since 2002 www.rubberimpex.com Sitemap XIAMEN RPM IMP.&EXP. CO.,LTD. |