|

|

|

|

|

|

||||

| Made in China |

|

Medical Dental Grade TPI Granules, Synthetic Gutta Percha, Trans PolyIsoprene, TPI, Trans Isoprene Rubber, Trans-1,4-PolyIsoprene |  |

V-Belts |  |

China Largest Manufacturer of Meteorological Balloons | ||

Rimpex@RPM supplies v-belts including wrapped v-belts, cogged v-belts, narrow wedge wrapped v-belts, poly ribs v-belts, banded classical v-belts, banded narrow wedge v-belts, industrial t-teeth timing belts, agricultural v-belts, industrial curvilinear teeth timing belts, double v-belts, conveyor belts, delivery v-belts and raw edge cogged v-belts, etc. which are made of rubbers (polyesters) and fabrics (nylon), with features such as heat resistant, and/or oil resistant, and/or high temperature resistant, and/or chemical resistant, and/or cold resistant, etc.

The manufacturer locates in Kaifeng city, which was once the capital of seven dynasties in China, it is a key and high-tech enterprise of rubber products with rubber/plastic modification R&D works as its core, it integrates production, sales, R&D and services into a whole solution, and mainly produces rubber v-belts, conveyor v-belts, cut-edged v-belts, industrial fabrics, etc. as China famous brand. The manufacturer has won titles including вҖңHenan Province AAA Industrial Enterprises of Quality and Integrity", "Standardized Good Behavior Enterprise" and "Top 100 Henan Private Enterprises in Manufacturing IndustryвҖ? it also has taken the lead in passing various system certifications in the industry such as ISO9001, ISO14001, OHHAS18001, Integration of IT Application with Industrialization IQS Implementation System Certification, Product Quality Credit Certification, and Safety Mark Certification on Mining Products.The manufacturer is the vice-chairman unit of the rubber hose and tape branch of China Rubber Association. It has been in the leading position in the industry for ten consecutive years, and has participated in the formulation of national and industry standards, and owns many national patents, its products are widely used in the industry of coal mine, steel, oil, textile and other industries, sold all over China and exported to many other countries and regions. With first-class production technology and excellent product quality, the manufacturer will adhere to the business philosophy of вҖңearnest working, being honest, win-win results and continuous success" and move ahead pragmatically.

01 V-Belts Manufacturer Office, Factory |

02 Safety Certificate of Approval for Mining Products |

03 Environment and Quality Management System Certification Certificates |

04 Invention Patent and Occupational Health and Safety Management System Certification |

05 V-Belts Experimental Equipment in Lab of V-Belts Manufacturer |

06 V-Belts Experimental Equipment in Lab of V-Belts Manufacturer |

07 V-Belts Productive Equipment in Lab of V-Belts Manufacturer |

08 V-Belts Productive Equipment in Lab of V-Belts Manufacturer |

09 V-Belts Productive Equipment in Lab of V-Belts Manufacturer |

10 Classical Wrapped V-Belts Y ZO A B C D E F |

11 Cogged V-Belts 3VX 5VX 8VX XPZ XPA XPB XPC AX BX CX |

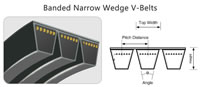

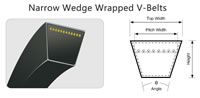

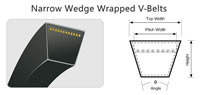

12 Narrow Wedge Wrapped V-Belts 3V9N 5V15N 8V25N SPZ SPA SPB SPC |

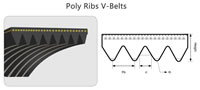

13 Poly Ribs V-Belts PH PJ PK PL PM - - |

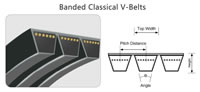

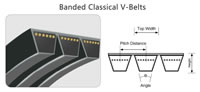

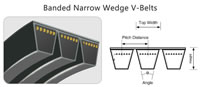

14 Banded Classical V-Belts HA HB HC HD AJ BJ CJ DJ Banded Narrow Wedge V-Belts 3V9J 5V15J 8V25J |

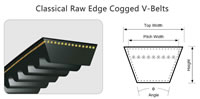

15 Industrial T-Teeth Timing Belts MXL XL L H XH XXH T2.5 T5 T10 T20 AT10 AT20 |

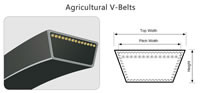

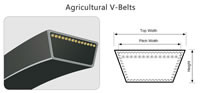

16 Agricultural V-Belts HI HJ HK HL HM - - |

17 Industrial Curvilinear Teeth Timing Belts H3M H5M H8M H14M H20M S3M S5M S8M S14M R3M R5M R8M R14M |

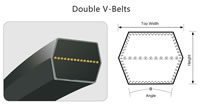

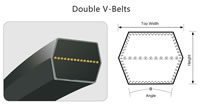

18 Double V-Belts HAA HBB HCC |

19 Delivery V-Belts Polyester, Nylon, Heat Resistant Conventional Oil Resistant High Temperature Resistant, Chemical Resistant Cold Resistant, Patterned, Endless Conveyor Belts |

20 Classical Wrapped V-Belts Section View Top Width Pitch Width Height Angle Y Z A B C D E - - - |

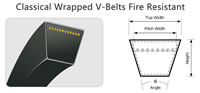

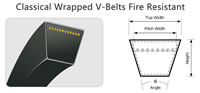

21 Classical Wrapped V-Belts Fire Resistant Section View Top Width Pitch Width Height Angle MVA MVB MVC MVD MVE - - - |

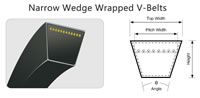

22 Narrow Wedge Wrapped V-Belts Section View Top Width Pitch Width Height Angle 3V9N 5V15N 8V25N SPZ SPA SPB SPC |

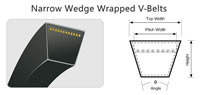

23 Narrow Wedge Wrapped V-Belts Fire Resistant Section View Top Width Pitch Width Height Angle MV3V9N MV5V15N MV8V25N MVSPZ MVSPA MVSPB MVSPC |

24 Banded Classical V-Belts Section View Top Width Pitch Width Height Angle AJ BJ CJ DJ - |

25 Banded Narrow Wedge V-Belts Section View Top Width Pitch Width Height Angle 3V9J 5V15J 8V25J SPZ SPA SPB SPC |

26 Agricultural V-Belts Section View Top Width Pitch Width Height Angle HI HJ HK HL HM |

27 Double V-Belts Section View Top Width Pitch Width Height Angle HAA HBB HCC |

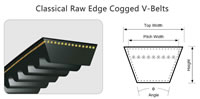

28 Classical Raw Edge Cogged V-Belts Section View Top Width Pitch Width Height Angle ZX AX BX CX |

29 Narrow Wedge Raw Edge Cogged V-Belts Section View Top Width Pitch Width Height Angle 3VX9N 5VX15N XPZ XPA XPB XPC |

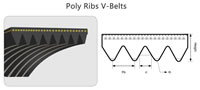

30 Poly Ribs V-Belts Section View Top Width Pitch Width Height Angle PH PJ PK PL PM |

31 Industrial T Teeth Timing Belts Section View Top Width Pitch Width Height Angle MXL XL L H XH XXH T2.5 T5 T10 T2660 AT5 AT10 AT20 |

32 Industrial Curvilinear Teeth Timing Belts Section View Top Width Pitch Width Height Angle H3M H5M H8M H14M H20M S3M S5M S8M S14M R3M R5M R8M R14M |

33 Nylon Delivery V-Belts Conveyor Belts NN100 NN150 N200 NN250 NN300 NN400 NN500 |

34 Polyester Delivery V-Belts Conveyor Belts EP80 EP100 EP150 EP200 EP250 EP300 EP350 EP400 EP500 |

35 Conventional Conveyor Belts H D L - |

|

21 Classical Wrapped V-Belts Fire Resistant Section View Top Width Pitch Width Height Angle MVA MVB MVC MVD MVE |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||

Features: |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

22 Narrow Wedge Wrapped V-Belts Section View Top Width Pitch Width Height Angle 3V9N 5V15N 8V25N SPZ SPA SPB SPC |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Features:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

23 Narrow Wedge Wrapped V-Belts Fire Resistant Section View Top Width Pitch Width Height Angle MV3V9N MV5V15N MV8V25N MVSPZ MVSPA MVSPB MVSPC |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Features: The flame-retardant narrow wrapped V-belt has large lateral rigidity, the transmission function is 50-100% higher than that of ordinary V-belts, the transmission limit speed is 44m/s, the transmission efficiency is more than 95%, flame retardant, antistatic, high temperature resistance, suitable for easy inflammable and explosive working environments. Identification Marks: Flame-retardant narrow wrapped V-belts are divided into two categories. One is the benchmark SP series, the models are SPZ, SPA, SPB, SPC; the other is the effective V series, the models are 3V (9N), 5V (15N) ), 8V(25N). The manufacturer marks the V-belt with the outer circumference. If the customer has special requirements, it must be indicated on the list of goods in order. The conversion relationship of various models is shown in the above table.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

24 Banded Classical V-Belts Section View Top Width Pitch Width Height Angle AJ BJ CJ DJ |

|

|||||||||||||||||||||||||||||||||||||||||||||

| Features: The combined common V-belt is connected by multiple single common V-belts through the connection layer. Make it into a whole, so that the force of each belt is even, and it can bear a larger load. During transmission, the problem of different lengths of multiple single V-belts used in combination is solved, with high transmission efficiency and longer service life. Identification Marks: The identification sequence of the common V-belt of the joint group is the model, the number of the joint group, the length dimension, and the length identification. The manufacturer marks the V-belt with the inner circumference. The conversion relationship of each model is shown in the above table.

|

||||||||||||||||||||||||||||||||||||||||||||||

25 Banded Narrow Wedge V-Belts Section View Top Width Pitch Width Height Angle 3V9J 5V15J 8V25J SPZ SPA SPB SPC |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Features: The combined narrow V-belt is connected through the connecting layer, so that multiple single narrow V-belts become a whole, so that each belt is evenly stressed and can withstand larger loads. When driving, the problem of different lengths is solved when multiple single V-belts are used in combination, high transmission efficiency and longer service life. Identification Marks: The identification sequence of the joint narrow V-belt is model, joint number, length dimension, and length identification. The company is marked by the outer circumference of the V belt. If the customer has special requirements, it should be noted on the goods list. The conversion relationship of each model is shown in the above table.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

26 Agricultural V-Belts Section View Top Width Pitch Width Height Angle HI HJ HK HL HM |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Features: The agricultural machinery V-belt has the characteristics of high strength, low elongation, large transmission power, stable transmission, good dimensional stability, convenient maintenance, and ability to absorb and resist instantaneous strong load impact. Identification Marks: The identification of the agricultural V-belt is marked by the length of the inner circumference. The conversion relationship of each model is shown in the above table.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

27 Double V-Belts Section View Top Width Pitch Width Height Angle HAA HBB HCC |

|

||||||||||||||||||||||||||||||||||||

| Features: The hexagonal belt (double-sided V-belt) has multiple working surfaces, good flexibility, and can be applied to multi-axis transmission such as textiles and agricultural machinery. Identification Marks: The identification of the hexagonal belt is marked by the reference length of the V belt. The conversion relationship of each model is shown in the above table.

|

|||||||||||||||||||||||||||||||||||||

28 Classical Raw Edge Cogged V-Belts Section View Top Width Pitch Width Height Angle ZX AX BX CX |

|

|||||||||||||||||||||||||||||||||||||||||||||

| Features: Ordinary classical raw edge cogged V-belts have the characteristics of wear resistance, low heat generation, large friction coefficient, low bending loss, high transmission efficiency, etc., can absorb transmission vibration noise, have a long service life, and have a fatigue resistance of up to 10^8 times. Identification Marks: The identification of ordinary classical raw edge cogged V-belt is marked by the inner circumference. The conversion relationship of each model is shown in the above table.

|

||||||||||||||||||||||||||||||||||||||||||||||

29 Narrow Wedge Raw Edge Cogged V-Belts Section View Top Width Pitch Width Height Angle 3VX9N 5VX15N XPZ XPA XPB XPC |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Features: The narrow wedge raw edge cogged V-belt has the characteristics of large friction coefficient, low bending loss, high transmission efficiency, etc., can absorb transmission vibration noise, long service life, and fatigue resistance. Identification Marks: Narrow wedge raw edge cogged V-belts are divided into two categories, one is the SP series based on the standard width, the models are XPZ, XPA, XPB, XPC, the other is the effective width V series, the models are 3VX, 5VX. The manufacturer marks the V-belt with the outer circumference. If the customer has special requirements, it must be indicated on the list of goods in order. The conversion relationship of each model is shown in the above table.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

30 Poly Ribs V-Belts Section View Top Width Pitch Width Height Angle PH PJ PK PL PM |

Note: The values of wedge distance and belt height are only reference dimensions. The cumulative error of the wedge distance is an important parameter, but it is affected by the working tension and the antibody's elastic modulus of the belt. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Features: Poly ribs V-belts have the comprehensive advantages of flat transmission belts and combined V-belts, low bending stress and centrifugal stress loss, high transmission efficiency, suitable for multi-axis transmission such as automobile engines, and high-power high-speed systems. Identification Marks: Poly ribs V-belts are generally divided into industrial V-ribbed belts and automotive V-ribbed belts. The models of industrial V-ribbed belts are PH, PJ, PhC, PL, PM, and automotive V-ribbed belts only use PK.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

31 Industrial T Teeth Timing Belts Section View Top Width Pitch Width Height Angle MXL XL L H XH XXH T2.5 T5 T10 T2660 AT5 AT10 AT20 |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Features: Industrial timing belts have the comprehensive advantages of belt transmission, chain transmission and gear transmission. They have the advantages of accurate transmission, stable transmission, low noise, no slip, and low bending loss. The transmission speed ratio can reach 10, the transmission limit speed reaches 50m/s, the transmission power is high, oil and humidity resistance, no lubrication, and adapt to multi-axis transmission..

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

32 Industrial Curvilinear Teeth Timing Belts Section View Top Width Pitch Width Height Angle H3M H5M H8M H14M H20M S3M S5M S8M S14M R3M R5M R8M R14M |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

33 Nylon Delivery V-Belts Conveyor Belts NN100 NN150 N200 NN250 NN300 NN400 NN500 |

Nylon Conveyor Belts are made of nylon canvas woven with nylon fiber as the framework materials and covered with high-performance rubber. It has the features such as thin belt, high strength, abrasion resistance, impact resistance, good groove formation, and strong adhesion between layers. It has the characteristics of excellent flexability performance and long service life. It is suitable for conveying materials with conditions such as medium and long distances, high load, high speed, and is widely used in mines, metallurgy, construction, ports, etc. Specifications and Technical Parameters of Nylon Multi-Layer Fabric-Core Conveyor Belts

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Adhesion and Elongation of Nylon Multi-Layer Fabric-Core Conveyor Belts

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

34 Polyester Delivery V-Belts Conveyor Belts EP80 EP100 EP150 EP200 EP250 EP300 EP350 EP400 EP500 |

Polyester Conveyor Belts are also called EP conveyor belts. Its skeleton material is polyester canvas interwoven with warp polyester and weft nylon. Its performance is characterized by low elongation in the warp direction and excellent troughing performance in the weft direction, and good water resistance, the wet strength does not decrease, no mildew occurs, and the initial modulus is high. It is suitable for conveying materials in the conditions such as medium and long distances, high loads, and high speed. Specifications and Technical Parameters of Polyester Multilayer Fabric-Core EP Conveyor Belts

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Adhesion and Elongation of Polyester Multilayer Fabric-Core EP Conveyor Belts

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Heat-Resistant Conveyor Belts Features: The belt cores of heat-resistant conveyor belts are made of cotton canvas and polyester canvas as the skeleton materials, and SBR and CR with good heat resistance are used as the covering rubber and buffer layer, which can be suitable for conveying materials with a temperature below 150В°C. It is widely used in cement, coking, metallurgy, steel and other industries.

|

||||||||||||||||||||||||||||||

35 Conventional Conveyor Belts H D L - |

Ordinary Conventional Conveyor Belts are glued together by multiple layers of rubber cotton (polyester + cotton) canvas, and covered with rubber on the top and bottom. The product implements the GB/T7984-2001 standard. Conveyor belt is the main part of belt conveyor, which plays the role of carrying materials. It is widely used in steel, coal, metallurgy, chemical, electric power, building materials, and food industries. Compared with other modes of transportation, the use of conveyor belt as a transportation carrier has the advantages of safe operation, convenient use, easy maintenance, low freight and continuity. This kind of conveyor belt is suitable for conveying bulk, granular and powdery materials at room temperature, which are without special corrosiveness under general conditions. Variety: According to the performance of the covering rubber, it can be divided into strong scratch type, strong wear type and general working conditions. Calculation method: square number of ordinary conventional conveyor belt = belt width * (number of fabric layers + (top rubber + bottom rubber)/1.5) * belt length |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Physical and Mechanical Properties of Cover Layer

Tensile Properties at Full Thickness: a. The longitudinal tensile strength of the belt shall not be lower than the following nominal values: 160, 200, 250, 315, 400N/mm b. The longitudinal elongation at break of the full thickness of the belt shall not be less than 10%, and the longitudinal reference force elongation of the full thickness of the belt shall not be greater than 4% Recommended Minimum Drive-Roller Diameter for Conveyor

Bonding Strength between Layers

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Oil Resistant Conveyor Belts 1. Product Features and Uses: Oil Resistant Conveyor Belts are made of cotton canvas, nylon canvas, and polyester canvas, which are refined through calendering, molding, vulcanization and other processes. Oil Resistant Conveyor Belts are suitable for conveying oily materials. 2. Technical Indicators: 2.1. The oil-resistant conveyor belts are divided into two types: wear-resistant (D type) and general (L) according to the performances of the cover rubbers. 2.2. Oil resistance is divided into Y1 and Y2 levels |

| High Temperature Resistant Conveyor Belts 1. Product Features: The belt cores of High Temperature Resistant Conveyor Belts are made of polyester canvas with high modulus, low shrinkage and extremely high tensile strength. The covering rubber is made of EPDM or chlorobutyl rubber with good high-temperature resistance, combined with high temperature resistant materials and refined through molding, vulcanization and other processes. After special immersion and shaping treatment, the belt cores of High Temperature Resistant Conveyor Belts have high adhesive strength. Under normal use conditions below 180в„? they have small elongation and excellent abrasion resistance performance. They can withstand high temperature of 250в„?in a short time. They are suitable for using in cement, coking, metallurgy, steel and other industries. Type and Specifications of High Temperature Resistant Conveyor Belts

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Acid/Alkali Resistant Conveyor Belts 1. Product Features: Acid/Alkali Resistant Conveyor Belt chooses cotton canvas, nylon canvas or polyester canvas as the belt core, the belt body has good elasticity, good groove forming performance, low elongation, and it is made of acid and alkali resistant materials. The covering layer has good chemical resistance and corrosion resistance, good physical properties. 2. Use: Acid/Alkali Resistant Conveyor Belt is suitable for chemical plants, fertilizer plants, paper mills and other factories and mining enterprises to transport corrosive materials such as acid or alkali. Technical Indexs of Acid/Alkali Resistant Conveyor Belts

|

|||||||||||||||||||||||

| Cold-Resistant Conveyor Belts 1. Product Features: Cold-Resistant Conveyor Belt choose cotton canvas, nylon canvas, and polyester canvas as the belt core, and the cover rubber is a combination of natural rubber and butadiene rubber. It has the characteristics of high elasticity, impact resistance, and cold resistance, and can be used normally under minus 40В°C. 2. Use: Cold-Resistant Conveyor Belt is suitable for conveying materials in open air or frozen warehouse in cold areas. 3. Technical Indicators: 3.1. The cold-resistant conveyor belts are divided into three types according to the performances of the cover rubbers: scratch-resistant (H), wear-resistant (D), and general (L) 3.2. Divided into two levels, C1 and C2, according to cold resistance. C1 used in environment temperature -45в„ғ~+50в„? C2 used in environment temperature -60в„ғ~+50в„?/td> |

| Pattern Conveyor Belts The pattern conveyor belt is composed of a belt body and a pattern part. Due to the different materials to be transported and the inclination of the conveyor, the shape and height of the pattern are required to be different. 1. Shape and characteristics: The surface has a "herringbone" pattern higher than the belt body, pit-shaped, or closed. Each pattern can be divided into three types: high, medium and low. 2. Purpose: Suitable for conveying powders, granulars and small pieces of materials with an inclination angle вү?0 degrees, and can also convey materials in packaging bags. |

| Endless Conveyor Belts Features: The endless conveyor belt is made into a jointless endless conveyor belt during its production process. Its characteristic is that the belt core has no joints and does not affect the service life due to early damage at the joints. The surface of the belt is flat and the tension is uniform, so the belt runs smoothly, The elongation is small in use. |

|

|

|

|

|

||

| rubberimpex.com | plasticimpex.com | mouldimpex.com | Loowi.com | GoldenPalaceGate.com | ||

| rubberplasticmould.com | ibmmachine.com |

moldimpex.com |

iLoowi.com | GoldenPalaceGate.cn | ||

| rpm.mobi | isbmmachine.com | masks machines | jindianmen.cn | |||

| wastetiresrecycle.com | printing-machines.cn | hot-stamping-machines.cn | hot-stamping-machines.com | logistics-forklifts.cn |

| Copyright © Rimpex@RPM Since 2002 www.rubberimpex.com Sitemap XIAMEN RPM IMP.&EXP. CO.,LTD. |