| WeChat: +86.13328318872 | Home | InSite Search | About Us | Contact Us |

|

|

|

||

|

||||

| Intellectualized Rubber Kneader Machinery Made in China Laboratory Intelligent Internal Mixer, Banbury Mixer |

|

Medical Dental Grade TPI Granules, Synthetic Gutta Percha, Trans PolyIsoprene, TPI, Trans Isoprene Rubber, Trans-1,4-PolyIsoprene |  |

V-Belts |  |

China Largest Manufacturer of Meteorological Balloons | ||

Rimpex@RPM supplies intellectualized rubber kneader machinery for rubber-carbon black masterbatch testing.

Laboratory Intelligent Internal Mixer BTM2-1 |

Laboratory Intelligent Internal Mixer BTM2-1 |

Technical Parameters of Laboratory Intelligent Internal Mixer

| Model | BTM2-1 |

BTM2-5 |

||

| Design Capacity: | 1 liter |

5 liters |

||

| Working Capacity: | 0.6-0.7 liter |

3.5 liters |

||

| Rear Rotor Speed: | 20-80rpm |

20-120rpm |

||

| Speed Ratio ofFront/Rear Rotors: | Shearing Type | 1:1.24 |

1:1.16 |

|

| Interlocking Type | 1:1 |

1:1 |

||

| Ram Piston Drive: | Hydraulic |

Hydraulic |

||

| Ram Piston Pressure on Rubber Materials: | 0.25-1MPa |

0-0.8MPa |

||

| Main Motor Power: | Shearing Type | 11KW |

37KW |

|

| Interlocking Type | 15KW |

45KW |

||

| Heating/Cooling Method: | Automatic Circulating Heat-Conducting Oil |

Mixing Chamber |

Independent Circulating Water Temperature Control System |

|

Rotor |

||||

Lower Ram |

||||

| Net Weight: | 1500Kgs |

2500Kgs |

||

| Overal Sizes: | 1500*610*1800mm |

2800*910*2100mm |

||

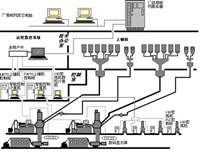

Intellectualized Innovation Sketchmap |

Rubber Kneader Internal Mixer Compounding Intelligent Control System MLJ300 |

Rubber Kneader Machinery Intellectualized System Display |

| Rubber Kneader Intelligent Control System (RKICS) Introduction |

Go Back Rubber Machinery Center

| Copyright © Rimpex@RPM Since 2002 www.rubberimpex.com Sitemap XIAMEN RPM IMP.&EXP. CO.,LTD. |