Rimpex@RPM supplies tyre machinery including bias OTR tyre tread winding equipment, radial OTR tyre tread winding equipment, laser speckle tire non destructive inspection system, laboratory intelligent internal mixer, internal mixer intelligent control system, tire tread contour cross section pattern figure detection inspectioin system, tire abrasion wear detection and analysis system,single roller die head, machine head, aircraft nose, pin cylinder barrel cold feeding extruder, conical twin screw extruding sheeter, conical twin screw extruding sheeting mill, up-stream equipments feeding system, tyre tread tire sidewall duplex extruding train line, rubber roller calender, complex extruders, right angle 90 cord fabric auto cutting splicer, tyre bead ring wrapping machine, tyre bead expanding inner appearance inspection machine, multi blade slitter, multitool longitudinal cutter, horizontal radial tyre apex applying to bead ring machine, polyethylene liner rubber belt big roll rewinder, tyre bead wrapping machine, all steel radial tyre coated cord fabric longitudinal cutting machine, tire cord ply vertical slitter, green tyres internal external surfaces lubricant isolating agent spray painting machine series, tyre parallel steel wires belt breaker cementing extruding line, tyre cord fabric vertical cutting production line, tire textile ply slitting production line, tyre apex strip extruding applying-up bead ring production line, tyre bead ring tire apex application Joint production line, all steel radial tyre apex apply-up line, finished tyres edging machine, tires letters colors recurrence, automatic weighting proportioning distributor, tyre enterprise MES manufacturing execution system, etc.

|

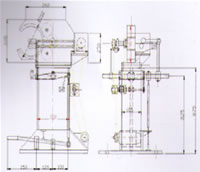

Bias OTR Tyre Tread Winding Equipment |

Applications: For bias OTR tread winding

Main Specifications:

Winding speed: 10-40m/min

Rotation speed of winding drum: 5-17rpm winding speed auto follows

Maximum winding width:

2100mm

Maximum thickness of wound tread: 180mm

Weight tolerance of wound tread: +/-2%

Thickness tolerance of winding tread: +/-1mm

Measuring resolution for tread thickness: less than 0.10mm

Strip size: width 50-100mm, thickness 5-10mm, cross section trapezium

Pressure of cylinder: 0.2-0.5MPa

Compressed air pressure: 0.6-0.8Mpa |

|

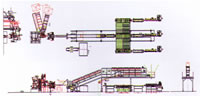

Radial OTR Tyre Tread Winding Equipment |

Radial OTR Tyre Tread Winding Equipment |

Radial OTR Tyre Tread Winding Equipment |

Applications: For radial OTR tread winding

Main Specifications:

Winding speed: 10-40m/min

Rotation speed of winding drum: 5-17rpm winding speed auto follows

Maximum winding width: 1000mm

Maximum thickness of wound tread: 100mm

Weight tolerance of wound tread: +/-3%

Thickness tolerance of winding: +/-2mm

Measuring resolution for tread thickness: less than 0.10mm

Strip size: width 50-100mm, thickness 5-10mm, cross section trapezium

|

|

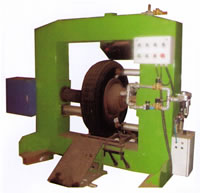

Laser Speckle Tire Non Destructive

Inspection System BTJSLNDT Series |

Laser Speckle Tire Non Destructive

Inspection System BTJSLNDT Series |

Laser Speckle Tire Non Destructive

Inspection System BTJSLNDT Series Interface |

Laser Speckle Tire Non Destructive

Inspection System BTJSLNDT Series Interface |

BTJSLNDT Series Tire Speckle and Nondestructive Laser Testsing System

Brief Introduction: BTJSLNDT series tire speckle and nondestructive laser testsing system is a new generation tire nondestructive test instrument that was researched and developped by China engineers. It is applicable to the tire quality detection in design, research and production enterprises, especially system becoming the most effective means to control the quality of aviation tires, steel radial car tires, and OTR tires. It also applies to retread tires, being an ideal device for test classification prior to tires retreading and quality test after retreading. This system is mainly used for detection of such defects as bubble and layers separation to prevent detective tires leave the factory, thus ensuring the safety of plane flight and automobile driving.

System Characteristics:

-

Usually according to the circumstance 360 angles, the surface of the tire can be divided into 6-12 sectors. Tires are delivered to a vacuum case horizontally before test. A measure probe stretched into the tire case and automatic placed for testing. This system has the high adaptability, it can measure any tire of different external diameter and sectional height. It also can take pictures outside.

-

The system can detect the tire inner defects and cause tire to attain high security standard, especially in the retreading industry, because any unqualified tire will be vanished in the pretreatment, so to avoid wasting manpower and resource and economy lost. After tire retreading, this equipment can detect the quality of the retreading tire whether up to the control equipment.

Applications: Apply to the aviation tire, car tire, trunk tire, OTR tire and retreading tire, not only for radials structure, but also for bias, besides the system also applies to the measurement of compound material articles.

-

BTJSLNDT 800 suitable to mini aviation tire and car tire

-

BTJSLNDT 1200 suitable to car tire, truck tire and OTR tire

-

BTJSLNDT 1600 suitable to truck tire, OTR tire and aviation tire

|

| |

BTJSLNDT800 |

BTJSLNDT1200 |

BTJSLNDT1600 |

Basic Parameter |

Optional |

Basic Parameter |

Optional |

Basic Parameter |

Optional |

| Measurement Light Source |

Laser |

- |

Laser |

- |

Laser |

- |

| Measurement Technology |

Laser Speckle Measurement Technology |

- |

Laser Shear Speckle Measurement Technology |

- |

Laser Shear Speckle Measurement Technology |

- |

| Measurement Probe |

1 |

- |

1 |

2 |

1 |

2 |

| Measurement Area |

Tire Surface |

Tyre Side & Tyre Bead Ring |

Tire Surface |

Tyre Side & Tyre Bead Ring |

Tire Surface |

Tyre Side & Tyre Bead Ring |

| Preparation of Tyre Carcass |

No Need |

- |

No Need |

- |

No Need |

- |

| Defective Resolution |

2mm |

- |

2mm |

- |

2mm |

- |

| Defective Type |

Air Bubbles, Delamination |

- |

Air Bubbles, Delamination |

- |

Air Bubbles, Delamination |

- |

| Reset Mode of Measurement Probe |

Full Automatic |

Manual Setting |

Full Automatic |

Manual Setting |

Full Automatic |

Manual Setting |

| Measurement Period |

<120 sec |

- |

<120 sec |

- |

<120 sec |

- |

| Tyre Size |

Minimum Inner Diameter 150mm |

Take Picture Outside |

Minimum Inner Diameter 300mm |

- |

Minimum Inner Diameter 150mm |

- |

Maximum Outside Diameter 800mm |

Maximum Outside Diameter 1200mm |

Take Picture Outside |

Maximum Outside Diameter 1600mm |

- |

| Cross Section Width |

400mm |

- |

450mm |

- |

600mm |

- |

| Laded/Disboard |

Active/Passive |

- |

Automatic |

User Interface |

Automatic |

User Interface |

| Defection Assessment |

Manual |

Full Automatic |

Manual |

Full Automatic |

Manual |

Full Automatic |

| Result Storage Modes |

Hard Disk or Optical Disk |

Others |

Hard Disk or Optical Disk |

Others |

Hard Disk or Optical Disk |

Others |

| Environment Request |

10-40 Degrees Celsius |

10-40 Degrees Celsius |

10-40 Degrees Celsius |

Tire carcass temperature is utmost 10 degrees Celsius higher than environment temperature. |

Tire carcass temperature is utmost 10 degrees Celsius higher than environment temperature. |

Tire carcass temperature is utmost 10 degrees Celsius higher than environment temperature. |

| Electricity Source |

220-380V 16A |

6Bar |

220-380V 16A |

Max.25A |

220-380V 16A |

Max.25A |

| Gas Source |

8Bar, 20L/min |

8Bar, 20L/min |

8Bar, 20L/min |

| Outline Dimension |

3.5*2*2m(L*W*H) |

- |

5.6*2.5*2m(L*W*H) |

- |

5.6*2.5*2m(L*W*H) |

- |

|

Laboratory Intelligent Internal Mixer |

Applications: For the research on macromolecular materials and macromolecular precision production

Main Specifications:

Model |

BTM-2-1 |

BTM-2-5 |

| Total Capacity of Mixing Chamber |

1 Cubic Liter |

5 Cubic Liter |

| Working Capacity of Mixing Chamber |

0.6-0.7 Cubic Liter |

3.5 Cubic Liter |

| Rotation Speed of Rear Rotor |

20-80rpm |

20-120rpm |

| Speed Ratio of Front/Rear Rotors |

Shear Type |

1:1.24 |

1:1.16 |

| Intermeshing Type |

1:1 |

1:1 |

| Driven by Top Ram |

Hydraulic |

Hydraulic |

| Pressure against Materials by Top Ram |

0.25-1MPa |

0-0.8MPa |

| Main Motor Power |

Shear Type |

11KW |

37KW |

| Intermeshing Type |

15KW |

45KW |

| Heating/Cooling Method of Internal Mixer |

Full Auto Heat Conducting Oil Cyclic Temperature Control System |

Mixing Chamber |

Independent Circulating Water Temperature Control System |

| Rotor |

Independent Circulating Water Temperature Control System |

| Lower Fastening Bolt |

Independent Circulating Water Temperature Control System |

| Net Weight |

1.5T |

2.5T |

| Overall Sizes |

1500*610*1800mm |

2800*910*2100mm |

|

|

Internal Mixer Intelligent Control System |

Functions of Intelligent Control System for Internal Mixer:

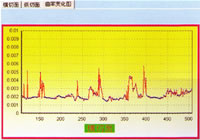

This system can record the moment power curve and relevant parameters of the entire mixing process of compounds, thus easy to analyze various properties of mixing rubber, and online predict the plastic (viscosity) value and dispersion index of mixing rubber. It is able to indicate curves of instantaneous power and temperature, shifts, operators, production time, variety of rubber kinds, production interval, auto or manual status, category of current action and type of full-auto failure to lead the mixer full auto mixing and to ensure the fluctuation of Mooney viscosity within +/- 4 (for 90% or more, controlled within +/-3) to increase dispersion by one level (stages mixing) as compared wtih the original process. This technology optimization can raise productivity by more than 5%.

|

|

Tire Tread Contour Cross Section

Pattern Figure

Detection Inspectioin System

- |

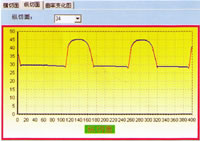

Functions of Tread Section Contour Inspection System:

Accurately measuring and recording tread contour (including width, thickness of each point and tread contour). Geometrical size and shape of tread can be displayed on the spot. It is able to diplay the change in thickness of any point along the length, only calculate the difference between the extrusion shape and set value, and provide real-time over-limit warning; inquiry and Excel introduction of extrusion information and statistics; printing of information on tread sections.

System Parameters:

-

Measuring veracity of tread width: +/-1.0mm

-

Measuring veracity of tread thickness: +/-0.1mm

-

Max.Tread Thickness: 40mm

-

Max.Tread Width: 1000mm

-

Max.Scanning Speed: 100mm/s

-

Electric Power (Single Section): AC220V 6A, Single Phase

Note: Measuring veracity is associated with max.tread thickness, scanning speed, surface inclination and working method, the max.tread thickness, the max.tread width, the power supply system and the max.scanning speed can be designed according to user's requirements. |

|

Tire Abrasion Wear

Detection And Analysis System

Curvature Variation Graph |

Tyre Abrasion Wear

Detection And Analysis System

Longitudinal Section |

Tire Abrasion Wear

Detection And Analysis System

Transverse Section |

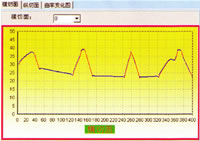

Functions of Tyre Abrasion Wear Detection and Analysis System

- 1. Information collection: when a tire rotates, the height of current monitoring point (relative to the tire axle center) can be calculated on a real time basis according to the position and reading of the laser head. After the tire turns one cycle, the height of one section of the tire can be detected. Detection continues after the laser head moves horizontally. In this way, the height of the entire tread can be measured.

- 2. Picture display: summarize the detected data, display traverse sections or longitudinal sections of tire and trace contour pictures according to the detect results. If the circumference of 360 degrees unbended to a plan, A contour picture and plan can also be obtained by comparison of the different value.

- 3. Calculation and comparison of abrasion data: compared with a standard tread and thus calculate the abrasions at different points. Comparison can also be made between abrasion treads after different mileages. Using different colors to distinguish severity of abrasion. The difference of abrasion can be ascertain.

- 4. Specification determination: tires with different specifications may vary greatly in outside diameter. The user can set a standard specification for different size tire. Then the laser head is able to move to a proper position automatically according to the preset data so as to get the measurement with optional precision.

- 5. Display of tire curvature: in accordance with detected data, the round degree of tire longitudinal section and change in curvature can be counted.

Applications: These series tire abrasion detector/abrasion instrument is applicable to the tire design, research and manufacture enterprises. This system is mainly used to inspect the severity of tires. It detects the abrasion of the same tread after running different mileages at the mileage counter, records and compares the datas.

|

|

Single Roller Die Head

Machine Head

Aircraft Nose |

Single Roller Die Head

Machine Head Aircraft Nose |

Applications: Applicable to the production of wide and thin rubber sheets, cushion rubber strips in combination with tension free curing of bead apex production line. The 0.2mm sheets of strips with width up to about 300mm. It also can be joint researched according to special requirements.

|

| No. |

Item |

Description |

| 1 |

Single Roller |

Integrated movable die head, convenient for maintenance |

| 1.1 |

Size |

Fi300*L500mm |

| 1.2 |

Roller Speed |

Max.70rpm, special speed can be set according to production requirements. |

| 1.3 |

Motor |

Integral SEW Frequency conversion motor 1KW, 1500r/min |

| Gearbox |

Integral SEW Gearbox, K series empty sleeve-shaft gearbox. |

| 1.4 |

Roller Structure |

Alloy steel mandrels, chilled cast roller surfaces, Strength and rigidity; chilled cast roller surface; HS70, 10mm thickness of chilling layer, ensuring service life. |

| 1.5 |

Adjust method of roll nip |

Worm-gear pair transmission |

| 1.6 |

Cutter |

Manual knife, 2pcs/set, 2 sets. |

| 1.7 |

Temperature Control Method |

RRC instrument adjusts temperature in PID |

| 2 |

Die |

Designed and manufactured as per use requirements, the changeable mouthpiece clamped through hydraulic pressure. |

| 3 |

Pressure Sensor |

Dynisco pressure & temperature |

| 4 |

Hydraulic Unit |

Haskel USA |

|

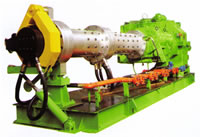

Pin Cylinder Barrel

Cold Feeding Extruder |

Applications: Applicable for the direct plastification, processing and profiling of compounds at a normal temperature or other processing production, such as extrusion of profiles, inter and outer rubber pipes, extruding for wire and cable cementing, provision of rubber to calendar and feeding rubber strips for OTR tire tread winding.

Main Specifications:

| Specification |

Fi60, Fi65 |

Fi90 |

Fi120 |

Fi150 |

Fi200 |

Fi250 |

| Screw Diameter, mm |

60, 65 |

90 |

120 |

150 |

200 |

250 |

| L/D Ratio |

12 |

12 |

12 |

16 |

18 |

18 |

12 |

16 |

16 |

12 |

12 |

12 |

| Max.Speed of Screw, rpm |

80 |

55-60 |

30-50 |

40-45 |

28-33 |

26-28 |

| Motor Power, KW |

22 |

55 |

110 |

220 |

315 |

500 |

18.5 |

45 |

75 |

160 |

220 |

315 |

| Max.Output Kg/h |

150 |

350 |

750 |

1500 |

2300 |

3500 |

180 |

400 |

850 |

1700 |

2600 |

5000 |

|

|

Conical Twin Screw Extruding Sheeter

BTXJYS 330/450/600 ZL |

Conical Twin Screw Extruding Sheeting Mill

BTXJYS 330/450/600 ZL |

Application: Suitable for mastication, mixing or final compounding from internal mixer of F270/F370, GK400/BB600, and extruding sheets in certain sizes.

Main Specifications:

- Working capacity: meet the requirement of auxiliary production for mixer with output of about 200L/300L/450L (such as F270, F370, GK400, BB600, etc.)

- Screw Type: double cone, single head, variable distance, variable depth, convergent type screw (unequal distance, unequal depth, convergent type, fully intermeshed, single head conical screw)

|

| Specification |

Fi330 |

Fi450 |

Fi600 |

| Output, ton |

9 |

13 |

28 |

| Linear Speed of Sheeter Roll, m/min |

4-36.5 |

4-42 |

5-55 |

| Roll Diameter, mm |

410 |

510 |

660 |

| Length of Roll Surface, mm |

1000 |

1100 |

1400 |

| Adjustment Clearance of Sheeter Roll (Electrically Adjusting) |

3-10 |

3-10 |

3-10 |

| Max.Lifting Height of Top Roll (Electricity Adjusting) |

200 |

250 |

300 |

| Max.Descending Depth of Bottom Roll (Electricity Adjusting) |

100 |

150 |

200 |

| Width of Extruded Sheet (Variable with Different Compound and Roll) |

-700 |

-800 |

-1000 |

|

Intelligent Internal Mixer

Up-Stream Equipments Feeding System |

Intelligent Internal Mixer

Up-Stream Equipments Feeding System |

Applications: it can be matched with various domestic & imported mixers of different models and specifications, such as 90, 160, 190, 270, 370 and 400.

Functions: this intelligent up-stream equipment is different from any other similar systems. It has not only the advantages of auto burdening and auto mixing but also:

- Auto optimization and adjustment of mixing process, overcoming quality fluctuation caused by raw materials, environment condition and other factors.

- Enhancing mixing compound quality, and ensuring the Mooney viscosity to be within +/-4 Mooney (in which 90% is within +/-3Mooney)

- Dispersion of carbon black in rubber compound doubles the original level

- Having the function of remote monitoring network

- Production efficiency increased by over 5% (as compared with the original technology)

|

|

Tyre Tread Tire Sidewall

Duplex Extruding Train Line |

Tyre Tread Tire Sidewall

Duplex Extruding Train Line |

Applications: used for take off components from the duplex extruder, compulsory contraction, breaker strip sticking or transition strip sticking, cooling, fixed length cutting, weighing, pick up and wind up processes.

Main Specifications:

- Width of conveyer belt of roller: 600-1000mm

- Linear speed of train: 3-45m/min

- Tread centering device: +/-1.0mm

- Cooling method: spraying + immersion

- Cutting precision: +/-3mm

- Tread cutting speed: max. 20times/min

- Temperature of cooling: less than room temperature +5 degrees Celsius (when the temperature of cooling water less than 25+/-5 degrees Celsius)

- Dimension: 75000L*5000W*6000H

|

|

Rubber Roller Calender

XYL360 |

Rubber Roller Calender XYL250 |

Applications: for ply up breaker strip to tread, It can be incorporated with tread & sidewall extruding train line, also used for calendaring rubber sheets.

Main Specifications of Calenders:

| |

XY-L360 |

XY-L250 |

| Roller Diameter |

360mm |

250mm |

| Roller Length |

900mm |

625mm |

| Ratio of Bottom/Top Rollers |

1:1.04 |

1:1.04 |

| Roller Linear Speed |

2-30m/min |

23.7m/min |

| Adjutable Rollers Distance |

0-10mm |

0-10mm |

| Min.Thickness of Calendering Sheets |

0.3mm |

0.3mm |

| Max.Width of Calendering Sheets |

650mm |

500mm |

|

|

Complex Extruders |

Complex Extruders |

Applications: for producing different profiles and assembled components of tire.

Duplex Extruders

Triplex Extruders |

Main Specifications of Duplex Extruders |

| Specifications |

Fi60/60 |

Fi90/60 |

Fi120/90 |

Fi150/90 |

Fi150/120 |

Fi200/150 |

Fi250(Hot)/150 |

Fi250/200 |

| Screw Diameter, mm |

60/60 |

90/60 |

120/90 |

150/90 |

150/120 |

200/150 |

250/150 |

250/200 |

| L/D Ratio |

12/12 |

12/12 |

14/12 |

16/12 |

16/14 |

16~18/16 |

8/16 |

16~18/16~18 |

| Max.Rotation Speed of Screw, r/min |

80/80 |

60/80 |

50/60 |

45/60 |

45/50 |

33/45 |

42/45 |

28/28~33 |

| Motor Power, KW |

18.5/18.5 |

55/18.5 |

90~110/55 |

185~220/55 |

185~220/90~110 |

315~355/185~220 |

220/185~220 |

500/315~355 |

| Max.Width of Extruding Product, mm |

150 |

|

450 |

|

|

550*35/650*35 |

550*35/650*35 |

650*40 |

| Derived Specifications |

|

|

|

|

|

|

|

Fi250(Hot)/200(Hot)

Fi250(Hot)/200

Fi200/200 |

| Max.Productivity, Kg/h |

180~250 |

350~450 |

1000 |

1200~1800 |

1500~2200 |

2500~3500 |

3500~450 |

4200~5500 |

| Note: Others combinations of Fi60~Fi250 also can be manufactured according to buyers' requirements. |

Main Specifications of Triplex (Quadruplex) Extruders |

| Specifications |

Fi200/150/120 |

Fi250/200/120 |

Fi120/200(Hot)/150 |

Fi90/120/200/150 |

| Screw Diameter, mm |

200/150/120 |

250/200/120 |

120/200/150 |

90/120/200/150 |

| L/D Ratio |

16~18/16/14~16 |

16~18/16~18/14~16 |

14~16/8/16 |

16/14~16/16~18/16 |

| Max.Rotation Speed of Screw, r/min |

28~33/45/50 |

28/28~33/50 |

50/50/45 |

60/50/28~33/45 |

| Motor Power, KW |

15~355/185~220/90~110 |

500/315~355/90~110 |

90~110/185/185~220 |

55/90~110/315~355/185~220 |

| Max.Width of Extruding Product, mm |

650 |

650 |

650 |

650 |

| Derived Specifications |

Fi200/150/120 |

|

|

|

| Max.Productivity, Kg/h |

3200~4200 |

4800~6000 |

3200~4200 |

3200~4200 |

| Note: Others combinations of Fi60~Fi250 also can be manufactured according to buyers' requirements. |

Right Angle 90

Cord Fabric Auto Cutting Splicer |

Applications: Textile ply cutting and splicing

Main Specifications:

Item |

Data |

| Max.Width of Ply before Cutting |

1500mm |

| Max.Diameter of Cord Ply Coil before Cutting |

950mm |

| Cutting Angle |

90 |

| Cutting Width |

320~880mm |

| Cutting Frequency |

14times/min |

| Ply Feeding Speed |

60m/min |

| Width of Liner |

1500mm |

| Cord Ply Storage Amount before Cutting |

3m |

| Max.Diameter of Winding Roll |

760mm |

|

|

Tyre Bead Ring Wrapping Machine |

Applications: for wrapping steel bead

Main Specifications:

- Main Eletrical Source: AC380V +/-10%, 50Hz +/-2%

- Control Power Supply: DV24V

- Application Range: Bead with size 12" 38"

- Diameter of Driving Press Roller: Fi42mm

- Rotation Speed of Gyration Gear Ring: 204rpm

- Motor Power: 0.55KW

|

|

Tyre Bead Expanding

Inner Appearance Inspection Machine |

Applications: for expanding tire bead in order to inspecting the inner appearance of tire.

Main Specifications:

- Bead Diameter: 20" 24.5"

- Compressed Air: 7Kg/cm2

- Power: 380V 50Hz

- Illuminating Light: DC24V or AC220V

|

|

Multi Blade Slitter

Multitool Longitudinal Cutter

- |

Applications: for slitting the rubber foils with plastic liner into various width as needed then wind-up for next process.

Main Specifications:

- Rubber Sheet Width: 600mm

- Mix.Cutting Width 20mm

- Size of Equipment: 5900*3100*1850mm

- Weight of Equipment: 2.5tons

|

|

Horizontal Radial Tyre Apex

Applying To Bead Ring Machine |

Applications: for applying-up apex to steel bead of radial tyres.

Main Specifications:

- Rotation Speed of Main Axis: 14.1rpm

- Height of Main Axis: 820mm

- Motor Power: 0.55KW

- Rotation Speed of Motor: 1410rpm

|

|

Polyethylene Liner Rubber Belt

Big Roll Rewinder

For

Tyre Bead Wrapping Machine Small Rolls |

Applications: for turning rubber belt with polyethylene liner from big roll to small roll which would be used on bead wrapping machine. Meanwhile, collecting and winding up the polyethylene liner onto a peel off shaft.

Main Specifications:

- Max. Decoiling Roll Diameter: 450mm

- Max. Coiling Roll Diameter: 200mm

- Max. Coiled Strip's Width: 40mm

|

|

All Steel Radial Tyre

Coated Cord Fabric

Longitudinal Cutting Machine

Tire Cord Ply Vertical Slitter |

Applications: for slitting coated cord fabric ply into several pieces at certain width, longitudinally on all steel radials tire process.

Main Specifications:

- Applicable Width of Cord Fabric: 1500mm

- Max. Cutting Width: 700mm

- Overall Dimensions: 7000*2500*2000mm

- Weight: ~4.5 tons

|

|

Green Tyres Internal External Surfaces

Lubricant Isolating Agent

Spray Painting Machine Series |

Green Tires Internal External Surfaces

Lubricant Isolating Agent

Spray Painting Machine Series |

Applications: for spray lubricant and solution on the inner/outer surface of green tires. |

|

Tyre Parallel Steel Wires Belt

Breaker Cementing Extruding Line |

Applications: used for extruding the two parallel steel wires, through arrangement, cementing, traction, cooling, storage and two stations coiling processes, to compose a continuous and automatic 0 degree steel wires belt breaker cementing production line.

Main Specifications:

- Screw Diameter: 90mm

- L/D Ratio: 12:1 (14:1)

- Max.Rotational Speed of Screw: 55rpm

- Max.Number of Ingots/Creels: 80pcs

- Linear Speed of Production: 115m/min

- Max.Width of Extruding Rubber: 138mm

- Number of Extruding Strips: 2pcs

- Thickness Range: 1.8+/-0.08mm

- Diameter of Cord Fabric Steel Wire: 0.85~1.06mm

|

|

Tyre Cord Fabric

Vertical Cutting Production Line

Tire Textile Ply Slitting Production Line |

Tyre Cord Fabric

Vertical Cutting Production Line

Tire Textile Ply Slitting Production Line |

Applications: for slitting textile ply (tyre cord fabric) in longitudinal direction.

Main Specifications:

- Cutting Knifes: Direct Cutting Type Paperknife

- Knifes Quantity: 8pcs

- Windup Coiling Mode: Passive

- Max.Diameter of Windup Coiling Roll: Fi500mm

- Let-off Square Steel's Diameter: 38*38mm

- Windup Coil Square Steel's Diameter: 38*38mm

- Power: 380V 3Phases 50Hz

- Air Source: 0.7MPa

|

|

Tyre Apex Strip Extruding

Applying-Up

Bead Ring Production Line |

Applications: It is used for conveying extruded & cooled apex strips by a conveyor belt to the apply up machine and adhere tyre apex on bead ring.

Main Specifications:

- Extruder: Fi90*14

- Cooling Unit: 5 rollers type (2+3)

- Linear Speed of Conveyer Belt: Max.14m/min

- Bead Diameter: 12"~16", 16"~24"

- Apex Height: 20-65mm

- Apex Thickness: Max. 12mm

- Cutting Precise of Tyre Apex: +/-1.5mm

- Temperature of Extrudates: Less than 125 degrees Celsius

|

|

Tyre Bead Ring Tire Apex

Application Joint Production Line

All Steel Radial Tyre Apex Apply-Up Line |

Applications: Cool tyre apex after being extruded from co-extruders, then deliver tyre apex by a conveyer belt to apply up machine for jointing tyre apex onto the bead ring.

Main Specifications:

- Diameter of Rubber Cemented Steel Wire: 1.60mm (Square Bead)

- Bead Inner Diameter B.I.D.: 19.5inch, 20inch, 22.5inch, 24.5inch

- Apex Height: 60~120mm

- Overlaps at Joints: 0~3mm

- Diviation of Apex: within 2mm

- Height Diviation of Apex: 0~3mm

|

|

Finished Tyres Edging Machine

BTMB Series For

Tires Letters Colors Recurrence |

Applications: Applicable to color recurrence of finished tire products.

Functions:

- Technical Parameters: Applicable tire specifications of light truck tires and terrain tires varying from R15" to R19.5"

- For tires of R17.5", the grinding time lasts for about 1 minute (unilateral)

- Grinding Degree: 0~3mm

- Grinding Width: Less than 60mm

- Tire Inflation Pressure: Less than 3Kgf/cm2

- Rotation Speed of Tire: up to 20rpm, adjustable

- Rotation Speed of Grinding Wheel: 2800rpm, adjustable

- Power Supply: 380V, 3 Phases, 4 Wires System

- Air Supply: 6Kgf/cm2 dewatered compressed air, diameter of air supply pipe 1"

|

|

Automatic Weighting

Proportioning Distributor

For Large Batches Chemical

Ingredients Powders Granulars |

Automatic Weighting

Proportioning Distributor System

For Large Batches Chemical

Ingredients Powders Granulars |

Applications: To meet the production requirements of automatic weighing and distributing large batches of small powders and granular materials for the tire manufacture, rubber processing, plastic processing, foods and pharmaceutical fields.

Characteristics: The system has many advantages such as quick distribution, high precision weighing, simple structure, exact positioning, easy operation, safety, reliability and less pollution. A series of all automatic and semi automatic types of system is available to supply various endusers.

|

|

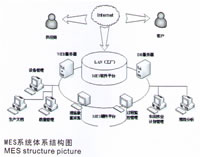

Tyre Enterprise

Manufacturing Execution System

MES |

MES, Manufacturing Execution System, which is an execution layer between plan layer and site operation control layer, is mainly in charge of production management and schedule execution. Its main function includes operating plan and arranging production, managing technical specification standard, collecting data, managing production employees, products output managemetn, processes management, maintaining equipments and the following up managements of new products and so on.

The implement effects of MES system are listed as following:

- It realizes the remote real time monitoring and control on the running conditions of production equipments. The production plan can be updated remotely at real time, it can get locale process parameters, yield counting information and status of equipments. It not only intensifies decision basis, but also raise response speed on locale accidents, it improves the former condition that information lost, information distortion, information delay in the artificial reports works.

- The system has powerful comprehensive inquiry function, it can inquiry parameters of recipes, historical datas, production conditions, quality requirements anytime, so that it is convenient for production quality tracking.

- It realizes some functions like inquiry of job handover, absence count, every batch production's quantity count, it improves management level to a higher step.

- It uses historical datas to build static optimization model, so it can make control strategy on the basis of stable quality and lower energy consumption.

|

|

00 Closed Planer Double Housing Planer

Planing Machine B2020A1 |

00 Italy Giant Numerical Control

NC Boring Milling Machine |

00 Italy Giant Numerical Control

NC Profiling Milling Machine |

00 Large Plate Guillotine Shears Clipper

- |

00 West Germany Numerical Control

NC Screw Processing Machine |

|

Go Back Rubber Machinery Center

|