Medical Parts

Liquid Silicone Rubber LSR Parts

For Syringes |

Medical Parts

Liquid Silicone Rubber LSR Parts

2 Cavities, Urine Urinary Catheter |

Medical Parts

Liquid Silicone Rubber LSR Parts

2 Cavities, Urine Urinary Catheters |

Medical Parts

Liquid Silicone Rubber LSR Parts

3 Cavities, Urine Urinary Catheter |

Medical Parts

Liquid Silicone Rubber LSR Parts

Face Masks |

Medical Parts

Liquid Silicone Rubber LSR Parts

First Aid Mask |

Medical Parts

Liquid Silicone Rubber LSR Parts

First Aid Mask 2 |

Medical Parts

Liquid Silicone Rubber LSR Parts

First Aid Mask 3 |

Medical Parts

Liquid Silicone Rubber LSR Parts

Health Care Cupping Jar, Fire Pot |

Medical Parts

Liquid Silicone Rubber LSR Parts

Laryngeal Mask |

Medical Parts

Liquid Silicone Rubber LSR Parts

Laryngeal Masks 2 |

Medical Parts

Liquid Silicone Rubber LSR Parts

Laryngeal Masks 7 |

Medical Parts

Liquid Silicone Rubber LSR Parts

Laryngeal Masks, 1st Generation |

Medical Parts

Liquid Silicone Rubber LSR Parts

Laryngeal Masks, 1st Generation a |

Medical Parts

Liquid Silicone Rubber LSR Parts

Laryngeal Masks, 1st Generation, Siamesed |

Medical Parts

Liquid Silicone Rubber LSR Parts

Laryngeal Masks, 2th Generation |

Medical Parts

Liquid Silicone Rubber LSR Parts

Laryngeal Masks, 3rd Generation |

Medical Parts

Liquid Silicone Rubber LSR Parts

Laryngeal Masks, 3rd Generation a |

Medical Parts

Liquid Silicone Rubber LSR Parts

Laryngeal Masks, 3rd Generation B |

Medical Parts

Liquid Silicone Rubber LSR Parts

Laryngeal Masks, 3rd Generation D |

Medical Parts

Liquid Silicone Rubber LSR Parts

Laryngeal Masks, 4th Generation |

Medical Parts

Liquid Silicone Rubber LSR Parts

Laryngotracheal Mask with Springs |

Medical Parts

Liquid Silicone Rubber LSR Parts

Laryngotracheal Mask with Springs b |

Medical Parts

Liquid Silicone Rubber LSR Parts

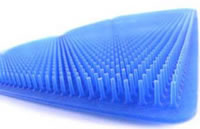

Medical Cushion Pad |

Medical Parts

Liquid Silicone Rubber LSR Parts

Negative Pressure Drainage Balls |

Medical Parts

Liquid Silicone Rubber LSR Parts

Negative Pressure Drainage Balls

100ml & 200ml |

Medical Parts

Liquid Silicone Rubber LSR Parts

Negative Pressure Drainage Balls 100ml |

Medical Parts

Liquid Silicone Rubber LSR Parts

Negative Pressure Drainage Balls 100ml |

Medical Parts

Liquid Silicone Rubber LSR Parts

Negative Pressure Drainage Balls A |

Medical Parts

Liquid Silicone Rubber LSR Parts

Respirator A |

Medical Parts

Liquid Silicone Rubber LSR Parts

Respirator B |

Medical Parts

Liquid Silicone Rubber LSR Parts

Respirator_C |

Medical Parts

Liquid Silicone Rubber LSR Parts

Pistons For Syringes |

Medical Parts

Liquid Silicone Rubber LSR

Seal Joints For Medical Devices

Baby Liquid Silicone Rubber LSR Nipples |

|

This machine is controlled by an AC servo control system, which helps increase dynamic response and torque density to the highest level and replaces the tradition driving modes adopting hydraulic, DC, stepping or AC frequency control mechanism. Such a configuration enables the system to have a shorter cycle, a higher production rate, better reliability and a longer service life. The entire AC servo system consists of a servo driver, a servo motor, an encoder and a load, which together runs in one control closed-loop system. Within the system, the driver receives information from the outside, and then transmits it to the servomotor, which converts the current into a torque and then passes it on to the load. Upon receipt of the torque, the load acts or accelerates or decelerates automatically, depending on its own characteristics. The encoder measures the position of the servomotor and feeds the signal generated back to the driver. Furthermore, the encoder is a high precision controller and can transmit modified values to the servo driver automatically, whereas the driver retroacts the set values. The entire system functions as a highly responsive closed-loop system. The DCM silica gel injection machine can save electricity by 40% to 80%, depending on the specific type of product. Normally, the thicker the glue layer of a product and the longer the cooling time, the less the electricity required.

Compared with conventional open-loop machines, the servo energy efficient silica gel injection machine (liquid silicone rubber LSR injection molding machine) enjoys the following features:

- Quicker response and higher precision (it takes only 50ms for a servomotor to reach its rated speed of revolutioin from a standstill; the repeatability of low voltage and low flow rate is +/- 0.5%; the hysteresis of the frequency conversion motor can be avoided)

- A shorter forming cycle and higher eficiency (the start and the stop of each operation are shorter thanks to the adoption of a servomotor; hydraulic leakage is reduced due to the cancellation of the comparison valve; the speed of revolution can be increased by 10% to 20% and hence a higher speed)

- Lower energy consumption on the part of the motor (the efficiency of a servomotor can be more than 90% while that of a conventional asynchronous motor is normally around 80%, which means that a DCM machine consumes less energy in realizing the same functionality)

- The current generated when starting a conventional motor is generally 5 times as high as that maintained when in normal operation. Because a DCM machine adopts soft start, it will not cause impact to the power grid.

- More water and oil-efficient (a high efficiency system can effectively avoid oil temperature rise, and therefore enable a smaller water cooling capacity and smaller temperature rise, which in turn reduces the rate of replacement for hydraulic oil.

- Lower noise

- A shorter machine body (a smaller unit length that enables efficient use of the plant's space)

- A higher cost-performance ratio (combining the merits of a hydraulic press with those of a complete motor)

|