11 Surgical Glove, Examination Glove, Disposable Glove

Dipping Machinery Production Line SBABC

|

Technical Parameters of

Surgical Glove, Examination Glove, Disposable Glove

Dipping Machinery Production Line

Model |

L*W*H

(m) |

Speed

(m/min) |

Capacity

(pcs/hr) |

Heat

(kcal/hr) |

Power

(KW/hr) |

Mold

(pcs) |

Chain

(m) |

Weight

(ton) |

SBA01 |

36m |

6.67 |

4,000 |

350,000 |

22 |

1,600 |

160 |

39 |

SBA02 |

60m |

10 |

6,000 |

550,000 |

34 |

2,400 |

240 |

44 |

SBA03 |

80m |

13.33 |

8,000 |

750,000 |

45 |

3,200 |

320 |

50 |

SBA04 |

100m |

15 |

9,000 |

820,000 |

53 |

4,000 |

400 |

65 |

SBC01 |

110m |

12 |

7,200 |

760,000 |

45 |

4,400 |

440 |

68 |

SBB01 |

60m*6 Chains |

15 |

9,000 |

820,000 |

50 |

3,600 |

360 |

60 |

SBB02 |

83m*6 Chains |

17.5 |

10,500 |

1,000,000 |

60 |

4,980 |

498 |

70 |

SBB03 |

100m*6 Chains |

20 |

12,000 |

1,100,000 |

70 |

6,000 |

600 |

80 |

|

21 Household Glove, Industrial Glove

Dipping Machinery Production Line RJAB |

22 Household Glove, Industrial Glove

Dipping Machinery Production Line RJAB |

23 Household Glove, Industrial Glove

Dipping Machinery Production Line RJAB |

24 Household Glove, Industrial Glove

Dipping Machinery Production Line RJAB |

25 Household Glove, Industrial Glove

Dipping Machinery Production Line RJAB |

26 Household Glove, Industrial Glove

Dipping Machinery Production Line RJAB |

Technical Parameters of Household Glove, Industrial Glove

Dipping Machinery Production Line

Model |

L*W*H

(m) |

Speed

(m/min) |

Capacity

(pcs/hr) |

Heat

(kcal/hr) |

Power

(KW/hr) |

Mold

(pcs) |

Chain

(m) |

Weight

(ton) |

RJA01 |

45*1.8*4.5 |

3.0 |

1,800 |

400,000 |

25 |

1,800 |

180 |

30 |

RJA02 |

80*1.8*4.5 |

6.0 |

3,600 |

600,000 |

48 |

3,200 |

320 |

55 |

RJA03 |

60m*6 Chains |

7.6 |

4,600 |

750,000 |

55 |

3,600 |

360 |

70 |

RJB01 |

110*2.2*4.5 |

11.0 |

7,200 |

820,000 |

53 |

4,400 |

440 |

68 |

|

31 Latex, NBR, PU Glove

Half Dipping Machinery Production Line SUBCD |

32 Latex, NBR, PU Glove

Half Dipping Machinery Production Line SUBCD |

33 Latex, NBR, PU Glove

Half Dipping Machinery Production Line SUBCD |

34 Latex, NBR, PU Glove

Half Dipping Machinery Production Line SUBCD |

35 Latex, NBR, PU Glove

Half Dipping Machinery Production Line SUBCD |

36 Latex, NBR, PU Glove

Half Dipping Machinery Production Line SUBCD |

37 Latex, NBR, PU Glove

Half Dipping Machinery Production Line SUBCD

Gloves

|

Technical Parameters of Latex, NBR, PU Gloves Half Dipping Machinery Production Line

Medium Quality Suitable for Latex |

| Model |

SUB8 |

SUB10 |

SUB12 |

| Dimension (m) |

30 |

30 |

30 |

| Row |

8 |

10 |

12 |

| Capacity (pcs/day) |

30,000-50,000 |

40,000-60,000 |

50,000-70,000 |

| Power (KW) |

3 |

4.5 |

5.5 |

| Mold (pcs) |

1,360 |

1,700 |

2,040 |

| Heat (kcal/hr) |

300,000 |

400,000 |

500,000 |

High Quality Suitable for Latex/NBR/PU |

| Model |

SUC8 |

SUC10 |

SUC12 |

| Dimension (m) |

32 |

32 |

32 |

| Row |

8 |

10 |

12 |

| Capacity (pcs/day) |

20,000 |

25,000 |

30,000 |

| Power (KW) |

3 |

4.5 |

5.5 |

| Mold (pcs) |

1,360 |

1,700 |

2,040 |

| Heat (kcal/hr) |

300,000 |

400,000 |

500,000 |

Super High Quality Suitable for Latex/NBR/PU |

| Model |

SUD6 |

- |

- |

| Dimension (m) |

18 |

- |

- |

| Row |

6 |

- |

- |

| Capacity (pcs/day) |

17,000 |

- |

- |

| Power (KW) |

3 |

- |

- |

| Mold (pcs) |

1,122 |

- |

- |

| Heat (kcal/hr) |

200,000 |

- |

- |

|

|

41 Latex Condom

Dipping Machinery Production Line |

42 Latex Condom

Dipping Machinery Production Line |

43 Latex Condom

Dipping Machinery Production Line |

44 Latex Condom

Dipping Machinery Production Line |

45 Latex Condom

Dipping Machinery Production Line |

46 Latex Condom

Dipping Machinery Production Line |

Technical Parameters of Latex Condom

Dipping Machinery Production Line

| L*W*H (m) |

52.2*2.3*4.5 |

| Single Production Capacity (pcs) |

80,000,000-100,000,000 |

| Mold (pcs) |

2,880 |

| Latex (ton/year) |

300 |

| Electric Power (KW) |

60 |

| Water (ton/hr) |

5 |

| Steam (ton/hr) |

1 |

|

51 Latex Balloon

Dipping Machinery Production Line QQ |

52 Latex Balloon

Dipping Machinery Production Line QQ |

53 Latex Balloon

Dipping Machinery Production Line QQ |

54 Latex Balloon

Dipping Machinery Production Line QQ |

55 Latex Balloon

Dipping Machinery Production Line QQ |

56 Latex Balloon

Dipping Machinery Production Line QQ |

Technical Parameters of Latex Balloon

Dipping Machinery Production Line

Model |

L*W*H

(m) |

Speed

(m/min) |

Capacity

(pcs/hr) |

Heat

(kcal/hr) |

Power

(KW/hr) |

Mold

(pcs) |

Chain

(m) |

Weight

(ton) |

QQ35 |

35*1.5*3 |

1.6667 |

5,000 |

320,000 |

21 |

3,600 |

90 |

40 |

QQ80 |

80*2.3*3 |

8 |

38,000 |

600,000 |

30 |

12,800 |

160 |

48 |

|

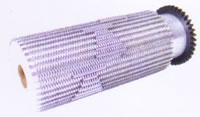

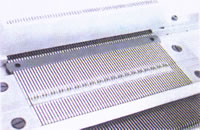

61 Automatic Glove Knitting Machinery |

62 Automatic Glove Knitting Machinery |

63 Automatic Glove Knitting Machinery |

64 Automatic Glove Knitting Machinery |

65 Automatic Glove Knitting Machinery |

66 Automatic Glove Knitting Machinery |

Technical Parameters of Automatic Glove Knitting Machinery

Automatic Glove Knitting Machine can knit different styles of glove such as 5-finger gloves, open finger gloves and jacquard bottom coupling gloves.

| Gauge |

7G, 10G, 13G |

| Motor |

250W |

| Voltage |

220V |

| Looking Station Rate |

15-20 sets per worker |

| Output |

360 pairs (7G) |

| Weight |

250Kgs |

| Machine Size |

1250*650*1750mm |

| Optional Auxiliary Equipments |

2-color device, 6-color knotter, sizes changing device |

| Auto Stop Motion: |

Yarn Breakage, Dropping Failure, Motor Overload, Elastic Yarn Breakage, Direction Error, Task Completed, etc. |

|

71 PVC Bead Points Dotting

Rubberizing, Embossing Machinery DZ |

72 PVC Bead Points Dotting,

Rubberizing, Embossing Machinery DZ |

|

73 PVC Bead Points Dotting,

Rubberizing, Embossing Machinery DZ

- |

74 PVC Bead Points Dotting,

Rubberizing, Embossing Machinery

DZ

- |

75 PVC Bead Points Dotting,

Rubberizing, Embossing Machinery DZ

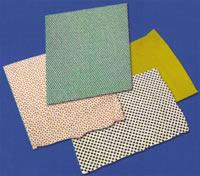

Finished PVC Fabrics |

Features:

-

This machine is used for synthesizing PVC point-bead on many kinds of clothes in the steamlined production.

-

It adopts the particular 635# heat-resistant chain transmittal structure, deliver the clothes simply and leveling off.

-

When this machine was designed, it made the most effective use of heating space, use heated air circulation principle and A4 PID temperature ratio control system, heating up quickly, enable it achieve the lowest cost.

-

It is made up with many factions, such as point-bead, gelatinize, press-grain, and helps you reduce the invest cost.

-

It is well designed, easily used, with less operation staffs.

-

It will be produced according to your special requirements, such as the width and yield of clothes, the space of workshop.

|

|