| WeChat: +86.13328318872 | Home | InSite Search | About Us | Contact Us |

|

|

|

||

|

||||

| Rimpex@RPM supplies TPI for tyres innovation on less rolling resistance & less dynamic heat build-up & good fatigue performance & good wear resistance. |

|

Medical Dental Grade TPI Granules, Synthetic Gutta Percha, Trans PolyIsoprene, TPI, Trans Isoprene Rubber, Trans-1,4-PolyIsoprene |  |

V-Belts |  |

China Largest Manufacturer of Meteorological Balloons | ||

Trans-PolyIsoprene Rubber (TPI)--- New Materials for Manufacturing High Performance Tyres

Written

by Professor Mr.Baochen Huang, Engineer Mr.Zhichao Zhao & Mr.Tao Deng

Translated by Rimpex Rubber, China

Following with the rapid development of China rubber industry, especially tyres manufacturing, now China's rubber consumption has exceeded USA's, that is, China is No.1 rubber consumption country in the world, China used up 4,500,000 metric tons in 2006. While China produced rubbers bless than half of that, so China imported many rubbers yearly, especially natural rubber (NR), i.e., in 2006, China produced NR 530,000 metric tons while imported 1,615,000 metric tons, which was nearly 1/5 of global NR output, so int'l NR market prices were kept in high level which brought heavy burdens on rubber (tyres) industry. Such situation would sustain for some time. It is an important task for synthetic rubber industry & rubber processing industry to develop substitutes of NR to reduce NR's application proportion. PolyIsoprene Rubber is the most ideal substitue of NR because its chemical composition and structure is similar with NR, both of them are polymer of isoprene. PolyIsoprene Rubber has two kinds, one is Cis-1,4-PolyIsoprene, which is also called as isoprene rubber, abbreviated as IR, it is a well known universal rubber in market; another is Trans-1,4-PolyIsoprene (TPI), or called as Trans-Polyisoprene Rubber, it is a new materials to be introduced hereinafter. Trans-Polyisoprene Rubber, scientific name is Trans-1,4-PolyIsoprene (TPI), also called as synthetic gutta-percha, synthetic balata, it is directionally polymerizated from isoprene. So TPI is isomer of isoprene rubber (IR) and natural rubber (NR). At room temperatures, TPI has easy crystallinity, looks like thermoplastic but with soften point around 60 degrees Celsius only, so it could be used directly to form all kinds of medical splints, orthopaedic materials, prosthetic materials, exercise and rehabilitation protect tools, etc. No extra moulds are needed if adopting TPI as models for body. TPI's molecular chain is essentially some unsaturated flexible chain (Tg around -60 degrees Celsius), so TPI could be crosslinked with same vulcanization method of unsaturated rubbers. If the crosslinking density is not so high, TPI is shape memory materials, that is, at room temperature it is a plastic with fixed shape, while at +60 degrees Celsius it is rubber elastomer with big deformation capacity. If the crosslinking density reaches some extend, because crosslink provents crystallization, TPI is turned into rubber elastomer. So you could see, TPI shows its different performances at different vulcanization stages, which could be used as functional materials for different applications. |

High Technology TPI Honoured |

TPI Applications |

TPI Production Workshop |

TPI Output |

1. Vulcanizing Properties of Trans-Polyisoprene Rubber TPI has same C=C double bonds density with NR, so they could adopt same curing system and have similar vulcanizing properties. Because crosslinking points provent TPI chain-segments' crystallization, the vulcanized TPI shows different 3 stages' properties according to different crosslinking densities. (Refer to Table 1) Table 1 - TPI's 3 Stages Properties & Applications

Because TPI's chain-segments have strong crystallization ability, so only high crosslinking density (4~6 portions) could turn TPI into elastomer, while at this status TPI shows properties of overcured rubber. So TPI being used for rubber products, is not used solely but with others rubbers. And TPI's contents in compound rubber are not more than 30%. |

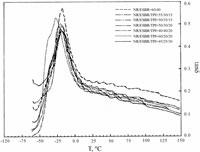

2. Dynamic Properties of TPI TPI could turn into elastomer by vulcanization or co curing with others rubbers. The test of dynamic viscosity & elasticity spectrum in Graph 1 shows that the vulcanized TPI has lowest rolling resistance and lowest heat produce among all rubbers ever used in tyres. The vulcanized TPI's 60 degrees Celsius tanδ value (Representating Roller Resistance) and 80 degrees Celsius tanδ value (Representating Heat Producing) are around 50% of ESBR, which are also much lower than NR, SSBR. Fewer TPI co cures with NR, SBR or others rubbers could obviously reduce compound rubbers' rolling resistance and heat producing while keeping various basic physical & mechanical properties. Refer to Graph 2. Lots of laboratory datas shows that those elastomers containing TPI have maximum characteristics as low rolling resistance, lower dynamic heat producing, good fatigue tolerance, improved wearable performance, which are all valued necessary properties for manufacturing high performances tyres. |

Graph 1 - T-tanδ Curves Contrast Of TPI & Rubbers |

Graph 2 - T-tanδ Curve Of Blended TPI & NR & ESBR |

3. TPI's applications in common tyres. Tyres are dynamic usage rubber products, whose main raw rubber materials are NR, SBR, BR, etc. TPI could be used as a portion of rubber compound recipe with NR, SBR, BR, etc. on tyre tread, tyre sidewall. Refer to Table 2 for physical & mechanical properties. Table 2 - Typical Composition Recipe & Main Properties of TPI in Tyre Tread & Tyre Sidewall [4]

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

The experimental results of TPI used in tyre treads of some cars tyres and light duty half steel wires radial tires are shown in Table 3: Table 3 - TPI Used in Tyre Tread Rubber in Little Batch Tyres Trial Production & The Test Result of Finished Tyres [5]

From the test results of Table 3, if only adopting 20~25 mass portions of TPI in tread rubber of car and light duty half steel wires radial tires, it could save fuel around 2.5%, and if adding extra 20 mass portions of HVBR into the tread rubber (sample C-2), then besides low fuel consumption, the wet skid resistance is also improved. So if a tire life is calculated as 100,000 kilometers (actual tire life is longer), each tire could save fuel 35 liters (car tire) to 50 liters (light duty tire), while only around 300~500g TPI is used in making such a tire. That is, if 1 metric ton TPI for tyres, it could save fuel 100,000 liters (70~80 metric tons), it could reduce carbon dioxide discharge of automotive exhaust around 200 metric tons. So the social & economic benefits are rather obvious. Tyres are the maximum application field of rubber raw materials, high performance energy-saving environmental tyres are in the trend of tyres development. According to the characteristics of synthetic TPI's vulcanized rubber, it could be aslo used in tyre sidewall, tyre apex, tyre belt, tyre lining, etc. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

4. TPI's applications in all steel radial tires and engineering tires. The all steel radial tires and engineering tires are development emphasis of many tyres enterprises, now mainly adopting NR with different curing systems (mostly adopting semi efficient curing system). Therefore, the performance of TPI & NR blend rubber is the key factor that if TPI could be used to partly substitue NR in all steel radial tires and engineering tires. Table 4 shows the performance of few TPI & NR blend vulcanized rubber with common sulphur curing system. Table 4 - TPI Dosage's Influences on TPI/NR Blend Rubber's Performances

From Table 4, we could see if less than 20 mass portions of TPI blended with NR, its vulcanization behavior and general mechanical properties like tensile strength, elongation at break, tearing strength, etc. are basically kept unchanged, while hardness, strength at definite elongation are rising following with TPI amount increased, and compression heat production, Akron abrasion loss are decreasing, the temperature scan characteristics (60 degrees Celsius Tgδ) also proves that rolling resistance is reduced. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Table 5 datas show that if adopting semi efficient curing system (DTDM as sulfur donor) to control well on dosage, then TPI could not only increase tensile strength and tearing strength and so on basic mechanical properties, but also further decrease rolling resistance and heat production. Table 5 DTDM Dosage's Influence on Properties of TPI/NR Blend Vulcanizate

HangZhou ZhongCe Rubber Co.,Ltd., CSTARC Tyre Research Institute, Triangle Tyre Group, DoubleStar Tyre and others tyre enterprises adopt new materials TPI made from out 500T/a intermediate test equipment and get similar results as shown in Table 5, which shows "to use 10~15 mass portions of TPI to replace NR is workable in manufacturing low-heat-production whole steel wires radial tyres and engineering tyres. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Our TPI technology has advantages in simple process flow chart, less investment, high efficiency, less energy & materials consumption, without three wastes, the synthesis cost is significantly decreased. Our TPI prices mainly depend on monomer price of isoprene, the metric ton consumption cost is around RMB3,500 plus monomer cost, which is much lower than common synthetic rubbers. Comparatively speaking, Cis-Polyisoprene Rubber (IR) and Trans-Polyisoprene Rubber (TPI) are both oriently polymerized from monomer isoprene, while IR adopts solution polymerization technology which requires huge solution (recycle, refine, circulation), its production process is complicated, high energy consumption. Our TPI adopts bulk precipitation polymerization without solution, its production process is simple, around 50% investment cost & 50% production energy consumption, so industrialized TPI's cost and price are surely lower than IR's. IR is synthesized to replace NR. Now TPI could play a more suitable role. With local government's support, our experts cooperate with related parties to register a legal company to push the progress of TPI industrialization. The 1st 500t/y industrial test plant has been built and trial run successfully in Dec., 2006, which could produce qualified TPI products. Now the company is testing TPI products from this 500t/y plant in tyres and others application fields, if market accepts it, then 10,000t/a industrial plant could be built (20,000t/a synthetic TPI industrial production plant is designing now) for large scale industrial production. At that time, TPI could be used as a new common rubber for tyres industry and various fields of the national economy. |

|

|

|

|

|

||

| rubberimpex.com | plasticimpex.com | mouldimpex.com | Loowi.com | GoldenPalaceGate.com | ||

| rubberplasticmould.com | ibmmachine.com |

moldimpex.com |

iLoowi.com | GoldenPalaceGate.cn | ||

| rpm.mobi | isbmmachine.com | masks machines | jindianmen.cn | |||

| wastetiresrecycle.com | printing-machines.cn | hot-stamping-machines.cn | hot-stamping-machines.com | logistics-forklifts.cn |

| Copyright © Rimpex@RPM Since 2002 www.rubberimpex.com Sitemap XIAMEN RPM IMP.&EXP. CO.,LTD. |